Blackburn Town Centre UID’s, Blackburn

The project objective was to resolve five unsatisfactory intermittent discharges (UID's) into the River Blakewater

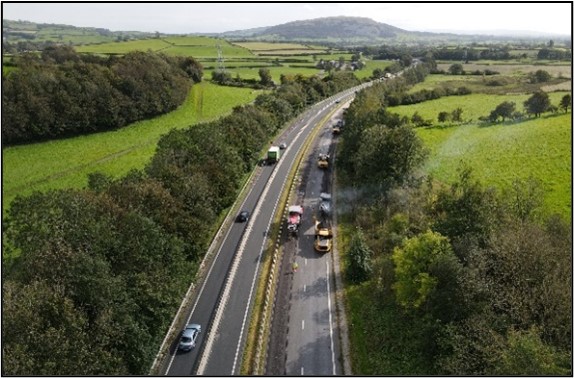

Read MoreProviding new acoustic barriers along M6. Resurfacing and lining improvements at the J44 Interchange roundabout on behalf of the LA. Resurfacing both north and southbound carriageways

Contract awarded through the HE Area 13 Construction Works Framework (CWF). AEY works included; Remove existing acoustic fencing and replace with 2.1km of 3m high Corten steel acoustic fencing; 1.5km of 1.8m high and 700m of 3m high close boarded S300 timber fencing; new traffic signals and associated ducting at J44; landscaping, ADS signage. AEY appointed as Principal Contractor for remaining works undertaken by other CWF Specialist Partners, including; 46 lane km of M6 carriageway surfacing; resurfacing of J44 roundabout; all associated traffic management. (NEC3 Option C)

The project objective was to resolve five unsatisfactory intermittent discharges (UID's) into the River Blakewater

Read More

Project to improve unsatisfactory intermittent discharges to local watercourses at two locations in Warrington.

Read More

Resurfacing and reconstruction of the busy A590 off the M6 near Kendal.

Read More

Reconstruction & widening of a partially collapsed double arch masonry road bridge over the River…

Read More