At SPI Piling Ltd, We like to make a real difference to all the projects on which we work. the best way to do this is, as they say, to get in there early.

Sadly for Specialist Contractors like us, this is extremely difficult, unless the Principal Contractors accept and invite our services.

We want to be sure that our clients receive the best possible service from all parts of our business and understand the benefits of inviting us in to their schemes early.

On traditional construction contracts, the client first appoints consultants to design the project in detail, and then the contractor is appointed to construct the works. However this can be seen to be a somewhat fragmented and adversarial project structure which does not give the contractor the opportunity to contribute to the development of the design that they will be required to construct.

At SPI Piling Ltd, we have worked with a number of our clients, both Contractors and Design / Engineering Consultants across the country in the scheme development stages. Not only as this helped the team in many ways, but we did it for Free!

Approaching the team here at SPI Piling Ltd early, can offer many benefits, like with an Early Contractor Involvement, such as;

- SPI Piling Ltd, Beginning the bespoke design process.

- Enhancing and Building a better team-working ethic.

- Introducing best practise and innovations.

- Advise on buildability, sequencing and construction risk.

- better program certainty from the out set.

- Advise on the selection of specialist plant and equipment in order to complete the works.

- Spend more time developing a construction strategy, identifying partners and so on.

- Help to develop a cost plan.

- Help develop the method / plan of other pre and post construction activities surrounding your piling requirements.

- Prepare a site layout plans for the construction stage.

- Assist with planning applications on matters concerning the build phase, such as construction traffic movements and tree protection.

ECI is particularly well-suited to all our specialist projects, but can be adopted on any project.

Early Design Involvement and how SPI Piling can help you further;

At SPI Piling Ltd, we have our very own expert design team, ranging from industry experienced engineers, to academically, and professionally qualified Civil Engineers, and Structural Engineers, as well as a huge experience in Ground and Geotechnical Engineering.

There are not many Specialist Steel Piling Contractors that can offer you this in house experience!

Focusing on feeding our vision of continuous improvement, eliminating waste reducing carbon and reducing cost, the Early Design involvement is key to these successes.

We want our clients to know that it is not simply about “a pile that works”, and that it is very much more than that, and very much centres around maximising the benefits, whilst reducing impacts.

Here is an example of what one of our clients said:

“The service I have personally witnessed from Ross MacMillan and Kennedy Chirwa, between them they have maintained momentum on the design and technical side of things whilst communicating very well with all parties including the geotechnical and structural engineers”

Two project examples where SPI Piling Ltd, had early involvement and it payed off.

Project C21298

The client intended to install to construct a basement for their multi-story block of flats. The proposed block of flats was in a combination of light industrial and residential settings.

Challenge

The ground conditions were such that there were sub-artesian groundwater pressures within what the pile lengths were expected to be. They had been around their traditional bored pile subcontractors who informed them that these conditions would pose challenges in the construction of a bored pile solution. So, the client had the idea to install a ‘water tight’ sheet piled cofferdam as temporary works to toe into the clay layer and act as a cut-off, then either construct an reinforced concrete basement or bring in the bored piled contractor to then install a bored piled solution on the inside as water pressures wouldn’t interfere with their construction in this scenario.

The client wanted different levels of water tightness within the basement too and the perimeter wall was to be load-bearing. On some elevations of the basement (neighbouring warehouse) was to have stringent vibration limits due to the sensitivity of equipment in the warehouse.

Solution.

What SPI Piling Ltd, was able to demonstrate to the client that sheet piles could also act as permanent works and that sheet piles also have the capability to resist a combination of loads, be it axial, tension, shear and/or bending moments. So, in their scenario, because we are driving preformed structures the sheet piles could act as a cut off (to create a dry working area on the inside of the cofferdam following pumping of water to below formation levels), but also as permanent works in resisting the loads from the superstructure and forming the basement area.

Our initial design and intention were to install sheet piles forming the basement on the 1st visit, then following excavation to formation level return to install CHS to act as bearing piles on the inside of the basement. After deliberations and number crunching it worked out cheaper and faster to install the sheet piles and the CHS in the same visit then cut off excess CHS upon excavation to formation. Yes, there would be the inconvenience of obstructions in the form of CHS but was still this option made sense. Furthermore, SPI made the assertion that ground conditions across the footprint of the site were fairly uniform, therefore yes, we would design the CHS using static pile calculation, but we would order and install a fraction of the CHS piles. From that fraction of installed CHS piles we carried out dynamic load testing, and then redesign the piles based on the test results as per Eurocode. This allowed us to shave off in the region of 1.5m off the pile length/pile and thereby pass on even more savings to the client and reduce the embedded carbon footprint of the structure.

With regards to waterproofing grades for the basement, the majority of the basement was to be a car park, therefore in line with BS8102:2009 fell in Class 1, in this zone we applied clutch sealant and formed water tightness this way. In the part of the basement that was to be plant room, this was to be Class 2 we welded the clutches of the piles to ensure no water penetration.

To reduce the irritation of noise and vibrations all piles (sheet and CHS) were vibrated into refusal before use if impact hammer. Vibration monitoring was installed in and around the site including neighbouring structures. On the elevation next to the warehouse with sensitive equipment the sheet piles were installed with vibration-less techniques.

Project C21396

The client wanted a temporary works sheet piled solution to retain a live rail track to allow them to excavate on the passive side for the installation of bored bearing piles for the widening of the A18 which runs underneath the rail track.

This project highlighted the value of early subcontractor involvement on schemes.

Challenge

We were grateful for the early subcontractor involvement, it meant that our ideas and solution evolved with the presentation of new information as and when it was presented. As a pre-existing structure the scheme was essentially evolving as the client carried out various exploratory works, yes there were historical as-built drawings but with more and more probing works it became apparent that the drawings weren’t quite accurate. The railway lines were live and therefore whatever proposals developed would have to be subject to Network rail approval.

At the time of receipt of the enquiry, it became apparent that the intrusive site investigation commenced at the bottom of the rail embankment. As we were essentially being asked to retain the rail embankment and tract it was vital that we had geotechnical information for the embankment. The client agreed and subsequently carried out further site investigation works from the top of the slope, but still wanted designs carried with available design for pricing and program purposes which invariably meant the designs would be carried out multiple times.

In essence, what became apparent was that we had to develop a scheme that would retain about 8m of embankment either side, with a live track at the crest and for the piles not to deflect more than 20mm at the head. It quickly became apparent that this design was going to be subject to a BC 5975:2008 Category 3 check. This effectively meant that once we had developed a solution an independent party will undertake design(s) without access to our design but merely drawings and philosophy and hopefully arrive at the same answers as we have.

What further complicated our design was that for example there were already existing ties on the bridge, so for one of our design revisions it then transpired that the proposed ties would clash with pre-existing ties. The sheet piles closer to the abutment would refuse on existing abutment foundations, therefore would need special measures but still adhere to the Network Rail performance specification.

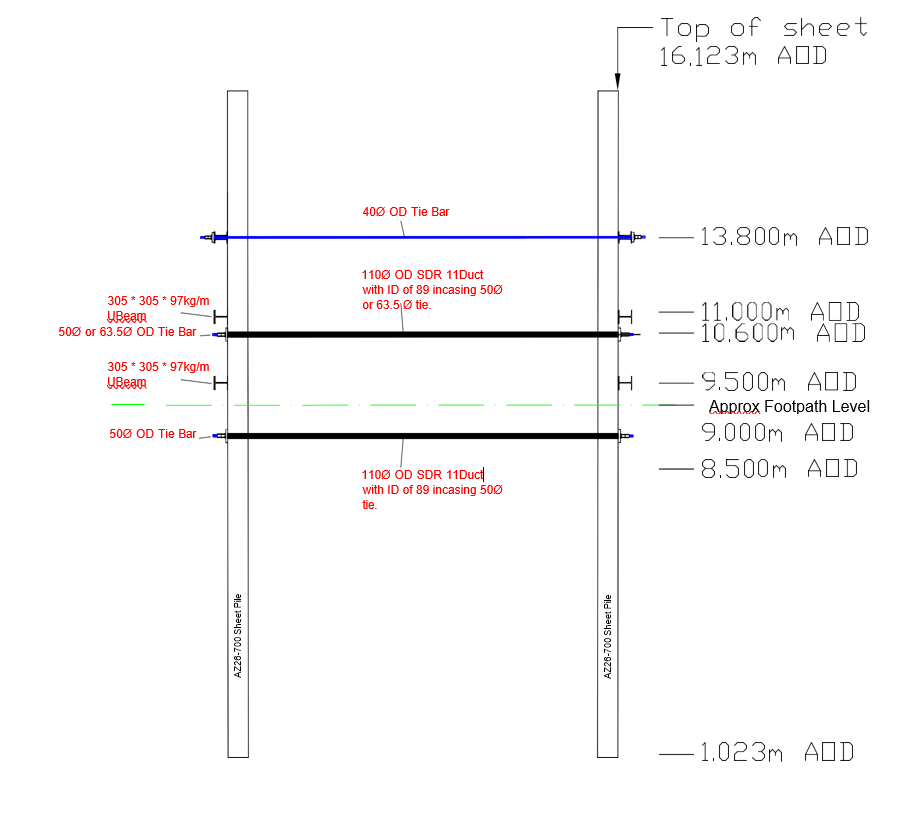

This whole process of receipt of tender to actually getting the design approved and signed by the Category 3 checker went on for over 12 months. The final solution involved 2 rows of sheet piles running parallel to the track with 3 levels of propping via ties as per diagram

Figure 1 Section Drawing

Ties were installed using our sister company A E Yates Directional Drilling.

Once the system had been installed it outperformed predicted performance. During calculations, the predicted pile deflection was 15mm yet on-site, as measured by the client themselves the actual deflections at the head of the pile didn’t surpass 6mm so they were more than happy with the outcome.

It was kind of sad seeing pictures of the system following dismantling after permanent works had been installed.