Net Zero – SPI Piling

Decarbonisation and the Journey to Net Zero is the most important aspect facing all industries and sectors, and is of key importance to us, our clients, and our supply chain. We are moving, along with our supply chain to align with the UK Government and European objectives and agreements, to reduce emissions, by the implementation of the new innovative products through the supply chain, the use of modern plant and equipment, exploring the use of better more sustainable fuels, and by reducing the amount of fuel consumption as a result of our normal business operations.

Some people would generally ask, how can the use of large new steel products possibly be sustainable?

Firstly and in simple terms, if you’re thinking of using piles as lets say foundations beneath your building, or even as a retaining structure within a harbour, the more traditional concrete approach may once have been the first solution you would think of, these piles would more than often be built in situ at the work site, requiring long construction durations, and thousands of material deliveries to enable the construction of the piles.

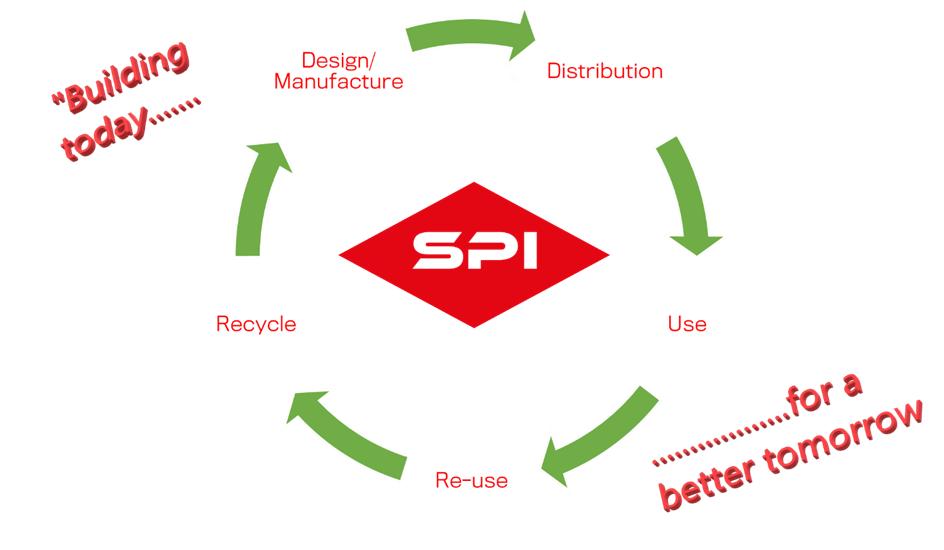

All structures have a design life according to the work they are doing and the environment they are situated. At the end of the design life of a building, structure or harbour wall, the structure would be demolished. The more traditional concrete structures are broken down and recycled into re-usable aggregates, HOWEVER, the foundations or elements much further below ground are left behind. They are unrecoverable, and thus are at the end of their useful life.

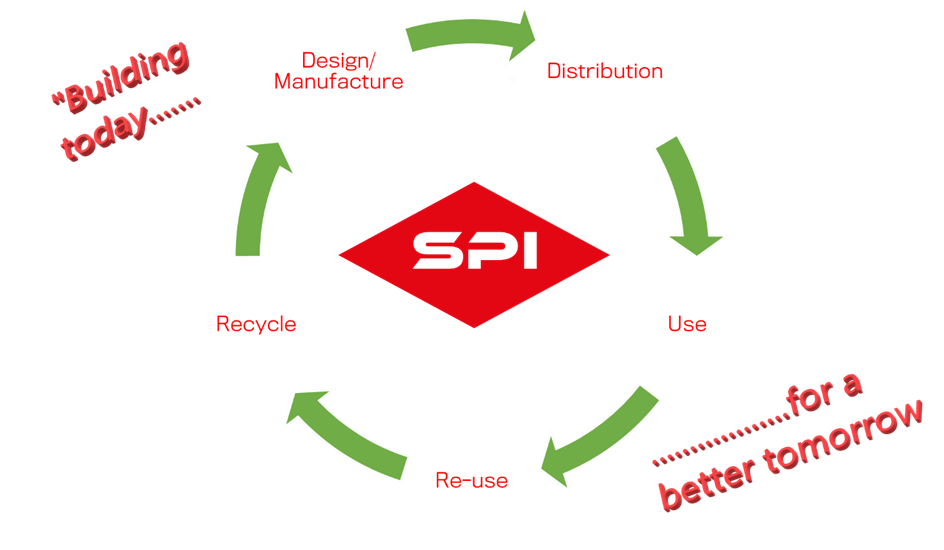

Steel piles however can be removed, extracted, and RECYCLED or REUSED (Repurposed) into other products or simply reused on another structure. This itself means that the USE of steel in this manner is entirely sustainable and is a major contributor to the circular economy.

Others would also ask; how can the production of New Steel be considered sustainable?

Europe’s largest steel sheet pile manufacturers have highlighted that steel piles can be reused between two and ten times without loss of any of their properties. Piles can be extracted from the ground, once they have served their purpose on a project, and can be reused on another site. Should a steel sheet pile have come to the end of its life it is 100% recyclable in an electric arc furnace enabling the material to be transformed into steel products that are of the same or enhanced quality.

ArcelorMittal was the first steel manufacturer to conduct a Life Cycle Assessment of its steel sheet piling products and it has also published an Environmental Product Declaration highlighting how seriously it takes its environmental responsibilities. We are a regular user of ArcelorMittal piles.

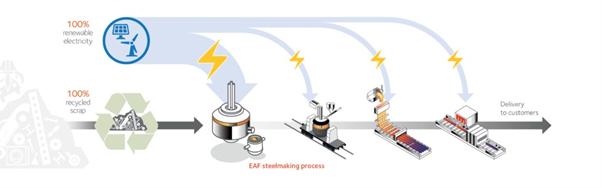

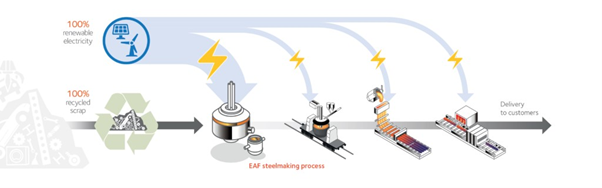

A prime example of this within the steel production sector is the Manufacture of steel through the Electric Arc Furnace (EAF).

Materials produced through the EAF process, have greatly reduced CO2 emissions typically less than 30% the value of products produced through normal blast furnace processes. As a typical example, previous processes would produce Circa 1.9tonnes of CO2 -eq per tonne of finished steel, whereas the EAF process reduces this to Circa 0.5tonnes of CO2 – eq per tonne of finished product.

Aside this Materials produced through the EAF process can be produced from 100% recycled material, as well as the options for these furnaces to be powered from renewable sources.

Looking a little bit further into the design of steel sheet piles. The key parameters for the choice of a section are the section modulus W (elastic or plastic) and the yield strength fy. In the allowable stress design method, the formula is quite simple:

M = Wel * fy with M = bending moment, Wel = elastic section modulus and fy. = Yield Strength.

Hence, if you increase the yield strength, you can reduce the required elastic section modulus proportionally.

In the 1950’s, a steel grade S355, with a yield strength of 355 MPa, was much more expensive than the standard S235, with fy = 235MPa. Today, steel sheet piles can be delivered with a yield strength up to 460MPa. Higher steel grades are slightly more expensive than a standard S355GP, but the cost difference is by far offset by the savings that can be made on the weight of the sheet pile section.

Rule: higher steel grades usually allow the selection of a lighter pile, thus reducing the environmental impact of a steel solution.

Additionally, the European design code EN1993-5 allows even to consider the plastic section modulus Wpl for class 2 sections, which means an additional increase of the resistance of a section between 10% and 25%!

Conclusion: innovation in steel and rolling technology, as well as installation equipment, made it possible to reduce the quantity of steel required to execute exactly the same retaining wall by more than 50% in a few decades. Besides, the solutions are cheaper than ever.

So what else are we doing at SPI Piling?

Plant & Equipment.

Over recent years SPI Piling has invested heavily in the upgrade of its prestigious fleet of piling equipment, to reduce emissions, improve efficiencies and employ the latest technologies to assist us on the way to Net Zero.

Our impressive ABI Fleet of piling rigs are fitted with Efficiency Drive technology, which in short improves the energy required to drive the piling attachments ensuring low fuel consumption, increased power and reduced noise.

This shortens our time on site by increased productivities (shorter construction periods), fuel savings on consumption meaning less fossil fuels burned, also resulting in less deliveries to site for the fuel itself in terms of the fuel and fuel storage requirements, Win Win!

We have also upgraded existing static plant such as generators and power packs to latest tier engine requirements.

SPI Also replace a complete fleet of excavators used with the Sidegrip attachments for installing piles. 3 Kobelco SK350, were purchased to replace the older more standard machines, reducing emissions, and fuel requirements similar to the leader rigs.

Steel Sheet Piles – Reuse

Steel sheet piles can be used and reused several times for temporary applications, thus reducing the environmental impact each time the sheets are re-used.

Europe’s largest steel sheet pile manufacturers have highlighted that steel piles can be reused between two and ten times without loss of any of their properties. Piles can be extracted from the ground, once they have served their purpose on a project, and can be reused on another site.

We encourage the re-use of steel piles through our holding of around 3000 tonnes of stock at our yard for projects requiring temporary sheet piles and ‘sale and buy-back’ options. Steel piles sold through either of these services are used in limited period scenarios. We carry a wide range of trench sheet, sheet piles and steel sections for sale or hire by customers and contractors.

Our inhouse designers make use of this facility to design projects using sections we hold wherever possible to offer the best economic benefit to clients.

SPI Piling continue to offer the best re-use model to all our clients. This promotes the effective re-use of steel products within the industry, and contributes to a reduced demand for new products and manufacture.

- short / medium term rental; clients can rent the sections they need for each project, optimizing the use of the steel or piles, as well as minimising project costs,

- sales and buy-back: after the end of the of a project (temporary application of sheet piles), the materials can be extracted and given back to SPI Piling Ltd, and the Piles purchased back into our stock (providing there is no excessive damage).

It goes without saying that at the end of life, when they cannot be reused anymore, 100% of the steel can be recycled.

SPI Piling are also a member of the A E Yates Group Charitable trust (GCT), Established in 2023 with one of the Charity objectives confirming its commitment to the environmental challenges that face us all by supporting Environment, conservation, and heritage.

The way in which this works is by the GCT making grants to individuals or organisations with the same commitments that the GCT is established to support, whether privately run or public services.