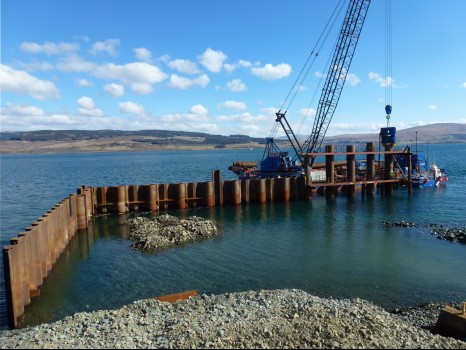

SPI Piling have worked on many major infrastructure projects across the UK. Marine works include port and harbour installations in the very north of Scotland, the Queensferry Bridge spanning the River Forth near Edinburgh and the Mersey Gateway Bridge. On the roads our work on National Highways’ Smart Motorway programme and motorway junction improvements have kept traffic flowing. We have kept the trains on track with a number of installations on the west and east coast mainlines and airside we have worked at Heathrow on Terminals 2 and 5. We don’t however forget what some may consider minor temporary works. Customers can therefore rest assured and be confident that we have the necessary in-house skills, capability and experience for all projects, no matter the size, nature or complexity.

We are also the ONLY specialist steel piling contractor in the UK that has the benefit of a Parent Company (A E Yates Limited). This provides substantial benefits when it comes to UK/EU buying power. Further bolstered by our extensive supply chain partner we ensure that customers feel the benefit of our procurement leverage with multiple major European and UK steel pile suppliers. The result is the realisation of the best possible value for money. Customers also benefit from the following range of services;

Supply, Installation, and Extraction

We offer a full supply, install, and extraction service for all types of steel and sheet piling using recognised suppliers or our own stock to provide value for money to customers. We also offer a ‘sale and buy back’ option. Steel piles sold through either of these services are used in limited period scenarios. We carry a wide range of trench sheet, steel and sheet piles for customers and contractors to buy or hire. Our in-group haulage or external partners, all fully registered to FORS and CLOCS standards, deliver nationwide. Sheet piles are suitable in many ground conditions and can be installed using vibratory, vibrationless or even percussive driving methods. Using our own specialist fleet of Telescopic Leader Rigs, Side Grip Technology, Silent Vibrationless and crane suspended equipment we offer installation and extraction in all sectors and applications for customers.

Leader Rig Installation:

We own and operate a comprehensive fleet of modern Telescopic Leader Rigs which can be fitted with a range of attachments to ensure that optimum performance and safety is achieved during sheet pile installation and extraction. The multi-functional Telescopic Leader Mast provides support for all attachments required for sheet pile driving, extraction, augering and static sheet pile pressing operations. This eliminates the requirement for traditional temporary works. In addition, the rigs have very short set up times (less than 30 minutes from transport to operational configuration) and the tracked carrier system offers high mobility on all construction sites. State of the art VV Technology and variable moment hammers ensure that vibration oscillations are reduced to a minimum. Consequently a considerable reduction in vibration is achieved during pile installation and extraction.

Silent & Vibration Free Piling:

The TOSA silent vibration free pile press enables piles to be installed and extracted in sensitive locations. Compact in size they are also ideally suited to height restricted sites such as inside buildings or under bridges. They hydraulically press piles into most soil types although, depending on ground stiffness or density, pre-augering or water jetting may be required. Following installation of the first three piles from a reaction stand the press travels along the installed piles using the reactionary force to press the next pile in (instead of using a hammering or vibratory action) creating very little noise or vibration. It is a self-travelling machine and does not need other machinery to assist it apart from a crane that lifts the pile into the chuck of the pile press. This installation methodology is common in densely urban areas where basement construction is part of the wider construction project. Hydraulic press attachments are also available for our Leader Rigs allowing greater outputs by installing piles in panels of four with no vibration.

Excavator Side Grip installation:

The Side Grip Hammer is attached to the end of the dipper arm of a 360º excavator (20tonne or 38tonne dependent on the unit being used). These units can be rotated vertically and horizontally offering high speed versatility in the correct applications. The Side Grip hammer is able to grip each pile from the side and drive the pile into the ground meaning these machines can be ideal in height constrained situations. The hammer can also drive tubular piles and posts and into embankments. The base machines can handle piles up to 12m long (longer piles may require additional plant in support or other considerations). The hammers are available in a range of sizes to suit various sizes of excavators. Pile accuracy is monitored via electronic instrumentation in the drivers cab. Side Grip technology offers optimised operation producing higher productivity and significant savings.

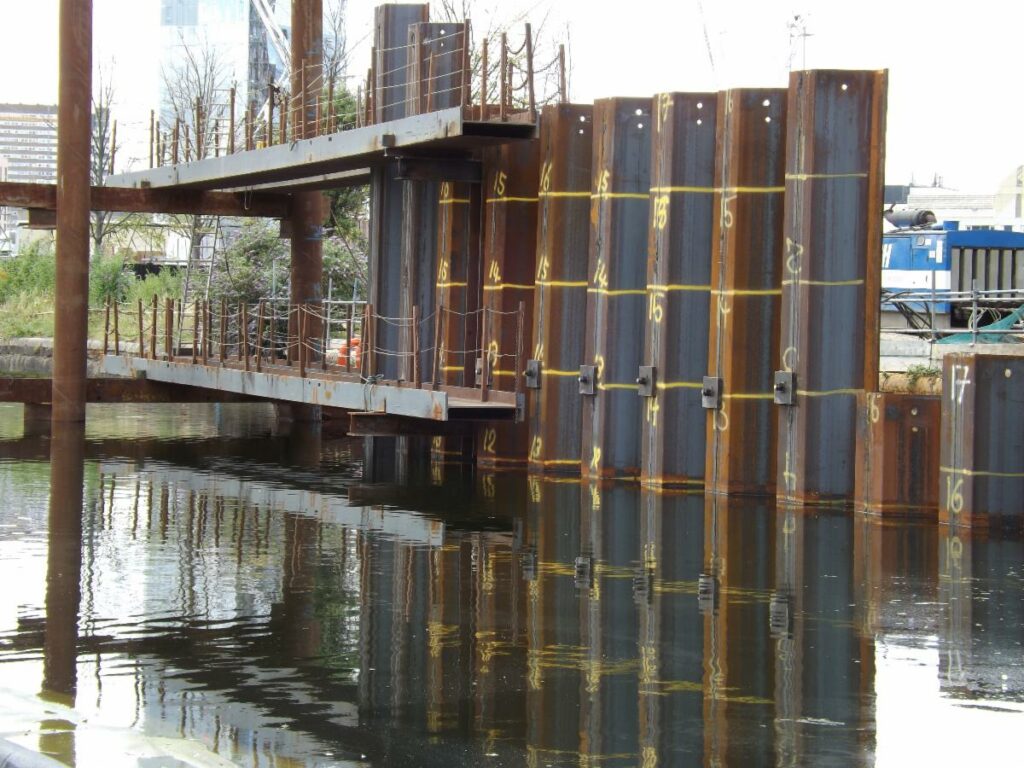

Steel Propping

Using various types of welding techniques our welders fabricate welded framing to support cofferdams, access jetties and other structures for both permanent and temporary requirements. We encourage the re-use of steel, holding around 1000 tonnes of steel section in stock at our yard for projects requiring temporary steel propping sections with a ‘sale and buy-back’ option. Steel sections sold through these services are used in temporary scenarios and we carry a wide range of sections for customers and contractors to buy or hire. A variety of bespoke temporary propping can be designed, fabricated and installed to any installation.

Conventional Installations

We are renowned for our expertise in working adjacent, or over, water on heavy marine installations and temporary works for large scale infrastructure requiring conventional installations. Conventional installation permits the installation of steel piles in areas with difficult land access or where platforms cannot be provided directly adjacent to the position of the piles being installed. This method is adopted where all modern methods of plant and equipment are unable to service the installation and involves careful planning and the use of large cranes and crane suspended piling equipment. Well equipped from our own stocks we are well placed in the market to provide this offering to all our customers where required, providing all the temporary materials and propping to enable this type of installation.

Design:

We employ a specialist in house design team of Civil Engineers and designers who can help you and your project from conception through construction to completion ensuring each project meets your requirements. We use industry standard design software packages to complete your designs providing cost effective solutions for all steel piling requirements whilst always maintaining a clear focus on safety, health, sustainability and quality throughout the design process. In more specialised areas such as environmentally sensitive areas, areas of outstanding natural beauty (AONB), SSSI, petrochemical, rail, highway and marine/coastal sectors we can provide designs to suit the criteria demanded. All designs are completed by experienced designers working to British Standards and EuroCodes.