New Technology

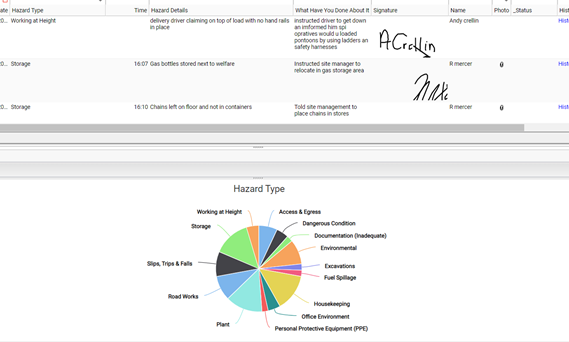

Our last newsletter focused on our Managing Director hosting our Annual Safety Day and the topics covered. Since then we have launched a mobile Application that is accessible to the entire workforce. The Application is in now being fully utilised and has vastly improved the flow of communication throughout the business. The App allows the workforce to engage at all levels in relation to anything HSQE related. It also facilitates real-time flow of information allowing us to keep clients informed as work progresses without the need to stop and fill out forms and paperwork and rely on the carrier pigeons to move it from A to B.

This simple step takes us further in our commitment to reduce our footprint in the environment and allows us to embrace the technology at our fingertips.

New Plant

You will be aware that in the final quarter of last year we made significant investment in our major plant fleet with the purchase of two new machines;

ABI HPZ Hydropress

Since our last newsletter this machine has been out working hard in sensitive areas from Manchester to London. Currently working hard in Stratford this attachment to the ABI Leader rig allows the silent vibration free installation of Z profile sheet piles. The added benefit of this particular attachment is the ability to safely and accurately press shorter pile sections for those smaller requirements or inner-city locations. We provide one rig with one mobilisation cost, with the ability to auger, pitch, drive and then press the piles!

Fantastic piece of kit! This coupled together with the state-of-the-art Efficiency Drive in our ABI Leader Rigs means an all round environmentally sensitive installation is achieved.

Kowan TOSA ZU100 Silent Piler

Since our last newsletter this machine has been out working hard in sensitive areas from Liverpool to Canterbury. The pile press is ahead of its competition in allowing the operator better visual aids in terms of health and safety monitoring of the installation and, equally importantly, providing live visual data advising on quality aspects that may occur during installation. The machine also boasts the self-travel support system as an added benefit and safety feature.

The Kowan ZU100 is a silent vibration free pile press enabling piles to be installed and extracted in sensitive locations. Compact in size they are also ideally suited to height restricted sites such as inside buildings or under bridges. They hydraulically press piles into most soils types although, depending on ground stiffness/density, pre-augering or water jetting is sometimes required.

Playing our part in the wider Environment

As we move into 2022 at pace we are pleased to be continuing to support Ghost Fishing UK in their quest and dedication in removing abandoned, lost and discarded fishing gear. This is one of the most difficult environments to remove waste left behind by human activity. The Ghost Fishing UK team do an exceptional job to save our marine environment.

As a business we are committed to ensuring our impact on the environment is minimal. Having strict policies regarding our environmental impact and the sustainability of the services we provide are key to our success. As such we are keen to support charitable organisations working hard to make a difference. We would like to congratulate Ghost Fishing UK on their achievements throughout last year and hope that their achievements grow in the coming seasons.

But you ask, “Just how sustainable are our activities in the steel piling sector?”

Sustainability – Just How Sustainable is Steel Piling?

Steel sheet pile manufacturers have highlighted that steel piles can be reused between two and ten times without loss of any of their properties. Piles can be extracted from the ground once they have served their purpose on a project and then reused on another site. Should a steel sheet pile have come to the end of its serviceable life it is 100% recyclable in an electric arc furnace enabling the material to be transformed into steel products that are of the same or enhanced quality. ArcelorMittal was the first steel manufacturer to conduct a Life Cycle Assessment of its steel sheet piling products and it has also published an Environmental Product Declaration highlighting how seriously it takes its environmental responsibilities.

Recycling Sheet Piles Through Hiring and Sale and Buy Back Facilities

We encourage the re-use of steel piles through our holding of over 3000 tonnes of stock at our yard for projects requiring temporary sheet piles and ‘sale and buy-back’ options. Steel piles sold through either of these services are used in limited period scenarios. We carry a wide range of trench sheet, sheet piles and steel sections for sale or hire by customers and contractors.

Our inhouse designers make use of this facility to design projects using sections we hold wherever possible to offer the best economic benefit to clients.

Working to minimise our Impact

A lot of projects can cause significant disturbance to the environments they are carried out in. Many things need to be considered within each project with regards to the environmental impact it will have on the local area, both during and after construction has finished. If these considerations are not made the projects would undoubtedly suffer delay and disruption. As part of the early planning process construction methodologies are some of the first considerations.

We have worked in many environmentally sensitive areas from inner cities where noise and vibrations to humans are the major concern to the pleasure of working in many rural and coastal/ marine environments. Whatever the scenario our specialist teams adopt the very best technologies when coming face to face with nature. We carry out specific planning processes for our specialist plant and equipment that helps rather than harms nature.