SPI Piling Ltd, would like to introduce a further two new additions to our ever-growing fleet!

Firstly, introducing our ABI HPZ Hydropress attachment.

As you can see the ABI HPZ Hydropress in all it’s glory, direct from the manufacturers, supplied by ABI EQUIPMENT LIMITED. This attachment will be added to our already impressive fleet.

This attachment compliments our modern fleet of ABI Telescopic Leader Rigs, allowing a silent vibration free installation of Z PROFILE Sheet Piles. The added benefit of this particular attachment is the ability to safely and accurately press shorter pile sections for those smaller requirements or inner-city locations. One Rig with One Mobilisation Cost, with the ability to auger, pitch, drive and then Press the piles!

Fantastic piece of kit!

This coupled together with the state-of-the-art Efficiency Drive in our(s), means an all-round environmentally sensitive installation is achieved.

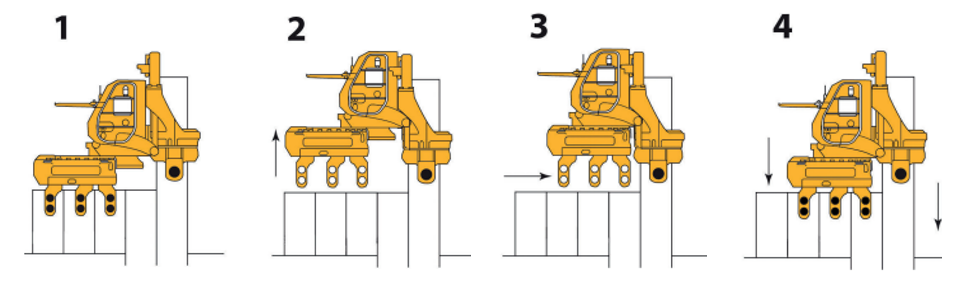

Secondly, our newest edition The Kowan ZU100 Pile Press.

The Kowan ZU100 Pile Press, seen here in all it’s Splendour, direct from the manufacturers, supplied and delivered by WATSON & HILLHOUSE. Again this machine will add to our already awe-inspiring fleet, and shows our continued commitment to improvement across all aspects of the business.

This machine is at the forefront of it’s competition, allowing the operators better visual aids in terms of health and safety monitoring of the installation, but also and equally as important live visual data advising on quality aspects that may occur during installation.

The machine also boasts the self-travel support system as an added benefit and safety feature.

The Kowan ZU100 is silent vibration free pile press enables piles to be installed and extracted in sensitive locations. Compact in size they are also ideally suited to height restricted sites such as inside buildings or under bridges. They hydraulically press piles into most soils types although, depending on ground stiffness/density, pre-augering or water jetting is sometimes required.

Following the installation of the first three or four piles from the reaction stand, the press travels along the installed piles using the reaction force to press the next pile in (instead of using a hammering or vibration action) creating very little noise or vibration, it is a self-travelling machine and does not need other machinery to assist it, apart from a crane that lifts the piles into the chuck of the pile press.

Thus, installation methodology is common in densely built up areas where basement construction is part of the wider project.