UIG HARBOUR

As you are aware from our previous news posts, SPI Piling Ltd are working on the UIG Harbour Redevelopment on behalf of R J McLeod.

The works commenced in March 2022 with the installation of the Fishermans Quay land-based sections. The work consisted of 200m of L606a x 15.0m sheet piles and 120m of L603 x 3.0m sheet piles for the anchor wall with the piles installed using our 17m rig with piles driven to level with the SL30 impact hammer.

15m long M76 tie bars were then installed at 2.4m centres to connect the main wall to the anchor wall with all activities serviced by a 100t crawler crane.

Throughout the construction works the Fisherman Quay is also used as a storage area of the steel piles and tubes which are transported via dumb barge on 3nr occasions throughout the works.

The marine section of the works is to install a new main berth which will widen the existing berth by 15.0m, this entails the installation of 914mm and 1320mm tubes up to 24.0m in depth with EZ28-700 infill piles to create the combi wall with the 2nr walls tied using M76 & M90 tie bars and also along the main approach a new line of piles (559mm diameter x 25m tubes) are installed to widen the approach by 8.0m. A new linkspan, bank seat, fender and dolphin piles are also installed.

The Marine section of the works are carried out from 2nr 250t jackup barges, on hire from R7M, with a 160t crane and 130t crane being utilised.

The first jackup mobilised to site in May with the second following on in August. All the marine operations are being assisted by DMS Condor and associated barges, on hire from Jenkins Marine.

Work is progressing well with the works and is due to complete in April 2023.

In Early 2023 there is a planned 8-week outage / closure of the harbour, when the ferry terminal will close to enable all essential works to be completed to keep ferry disruption to a minimum. To keep to this tight programme, a 300t crawler crane will also be mobilised to work from the new berth, this will involve a lot of logistical work to half rig the 300t crane, with the installation of additional tie bars to support the 300t crane, to enable it to be transported from the quayside to the new berth utilising the 250t jack up barge.

Our Piling Manager (Ronnie Head) and Project Manager (Mike Hunt) are pulling out all the stops to meet programme targets by working the site on a 12 day on 2 days off rota with a 12-hour working day.

This project is very complex in terms of planning and logistics, and from start to end will span a period of 10 months continuous site work for SPI Piling. This type of Project requires meticulous planning, which with the broader experiences of the team at SPI Piling Ltd, along with the support of our established supply chain partners, and the long-standing relationship with our clients is something that we carry out without hesitation.

FISH QUAY

The scheme is part of a wider project to regenerate North Shields and involves the construction of a new embankment walkway improving accessibility and linking the town centre to the popular area of Fish Quay.

The design requires the installation of seven separate sheet pile retaining walls, designed by SPI, to retain and provide global stability to the embankment while enabling the construction of the earth reinforced walls that form the walkways on the embankment. The works involve the supply and Installation of 206nr single ZZ36-700 and 186nr single ZZ28-700 sheet piles, 70m of welded steel waler beam, and 210m of welded steel capping beam. A combination of different plant, piling equipment, and methods are required to be utilised to overcome the challenges presented by the ground conditions, limited access, and steep topography of the site.

The first phase of the works commenced in November 2022 with the installation of the sheet pile walls at the top of the embankment, working within a road closure on Tyne Street and utilising a combination of ABI TM14/17 leader rig with pre-augering equipment, 35t Sidegrip Rig, and crane suspended SL30 and CX60 impact hammers. Installation works were supported by a 55t crawler and 90t mobile crane. On completion of the pile installation, steel waler beam and capping beam installation were carried out by a welding gang supported by 8t and 14t excavators.

The second phase of the works is due to re-commence in the June 2023 and will involve installation of the pile walls on the lower section of the embankment working within a road closure on Bell Street with a 100t crawler crane supporting installation with the Kowan ZU100 still worker with high pressure water jetting unit, crane suspended impact hammers, and 35t sidegrip rig.

The third, and most challenging phase involves the installation of the final two sheet pile walls within the middle section of the embankment slope and will be undertaken using a 250t crawler crane positioned on Tyne Street at the top of the embankment.

WOOD WHARF

SPI Piling Ltd, were employed to supply and install 292nr AZ36-700N single sheet piles, 15-17m long and associated tie rods and walings to form both temporary and permanent retaining walls to enable the construction of two new residential towers.

The piles were installed with our ZU100 silent and vibrationless piler serviced by an electric 160T crawler crane.

ROCKY LANE UNDERBRIDGE

SPI Piling Ltd, were employed to supply and install 115nr GU27N sheet piles, 11m long to form a temporary retaining wall with preaugering and leader rig and vibrating hammer.

To then supply and install two rows of duckbill type anchors, 116nr total 17-24m long through the sheet piles to act as anchors.

When the new railway bridge was constructed, We returned to site to extract the sheet piles with a 100T crane and suspended vibrating hammer.

TARVIN WWTW

SPI Piling Ltd have installed a single circular cofferdam in an existing wastewater treatment works.

The sheet piled cofferdam has been installed to facilitate the construction of an additional wastewater treatment basin which includes above and below ground structures.

This cofferdam comprised of 52nr ‘U’ profile sheet piles at 10m long and has been designed and installed in order to facilitate the extraction of all temporary works sheet piles for future use.

The wastewater treatment works in Tarvin serves the greater Tarvin area near Chester.

The site comprises an operational wastewater treatment works, which needed to remain fully operational during the piling works. The main offices to the site are located in the southeast at the entrance, with the main wastewater treatment facilities to the north.

The sheet piles were initially installed using the ABI TM14/17 leader rig which needed to work from within the cofferdam due to restricted access. Since the cofferdam consists of just 52 piles, the leader rig was only just able to fit within the cofferdams footprint to perform this function.

Circular cofferdams can be notoriously difficult to ‘close’, however the excellent work by the operatives meant that they were able to close the cofferdam without the requirement for a special welded connection.

SPI Piling Ltd subsequently returned to site to extract the sheet piles to be reused an subsequent projects and due to the restricted access this was performed using a crane and vibratory hammer.

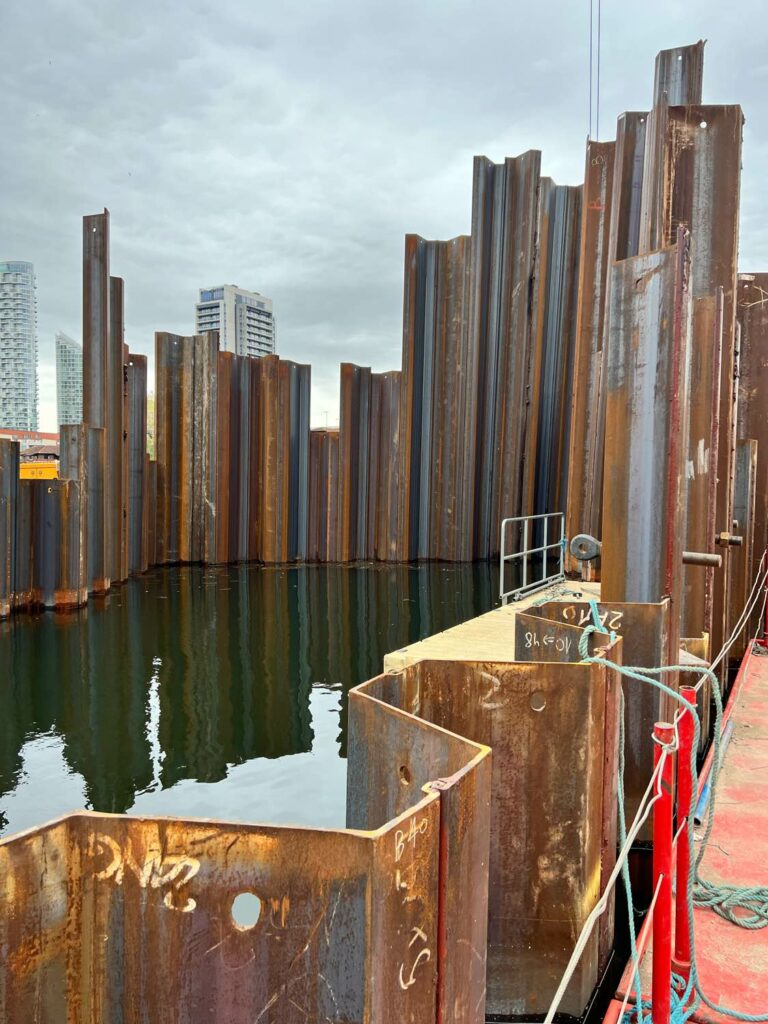

CANADA WATER

Redevelopment of the existing dock basin into a new residential and commercial area.

Due to our ongoing relationship, SPI were approached by Galldris to help them put together some costs for the piling works at Canada Water so they could agree figures with their client for a much larger project redeveloping the whole of the existing basin.

SPI designed and installed 2nr retaining walls totalling nearly 250m.

The Western Wall was installed close to water level with our excavator and side grip vibrating hammer to create a new park with water features to encourage the already abundant local wildlife.

The Southern Wall was installed with our silent and vibrationless piler. These piles were a lot longer and finished at a higher level so enabling the client to back fill behind it and create more leisure and shopping space.

In addition to this SPI supplied and installed 45nr tubular piles approximately 15m long to be used as foundations to support a new pedestrian boardwalk running at a higher level over the new park.

These piles were initially installed with our excavator and side grip vibrating hammer and then impacted with our BSP DX25 hydraulic impact hammer as the tubes were load bearing and subject to CAWAP Testing.

For all your steel piling needs contact your

“Steel Piling Contractor of Choice!”